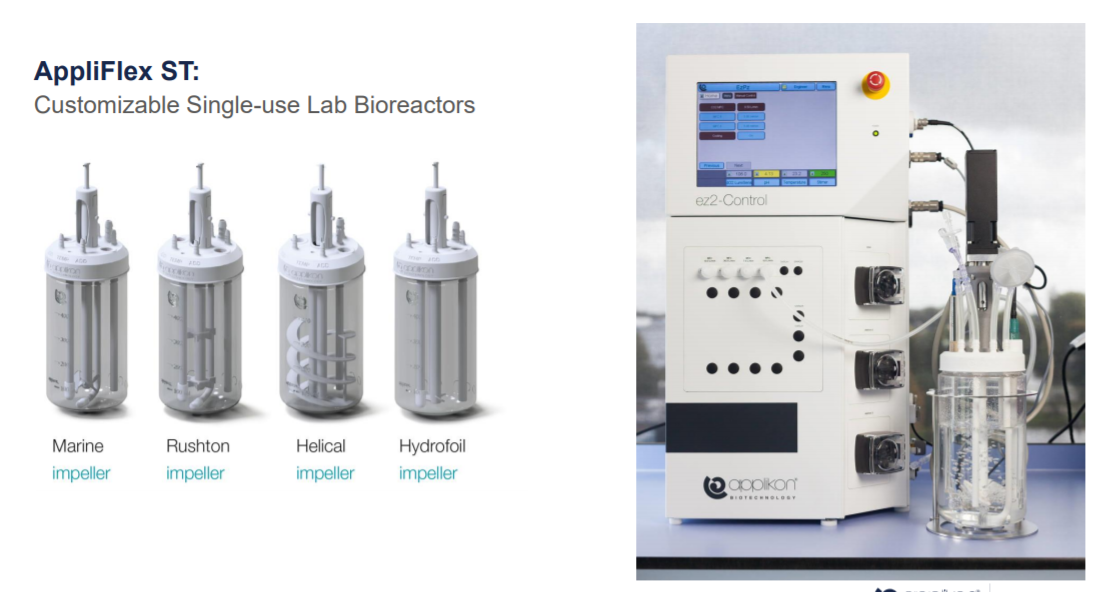

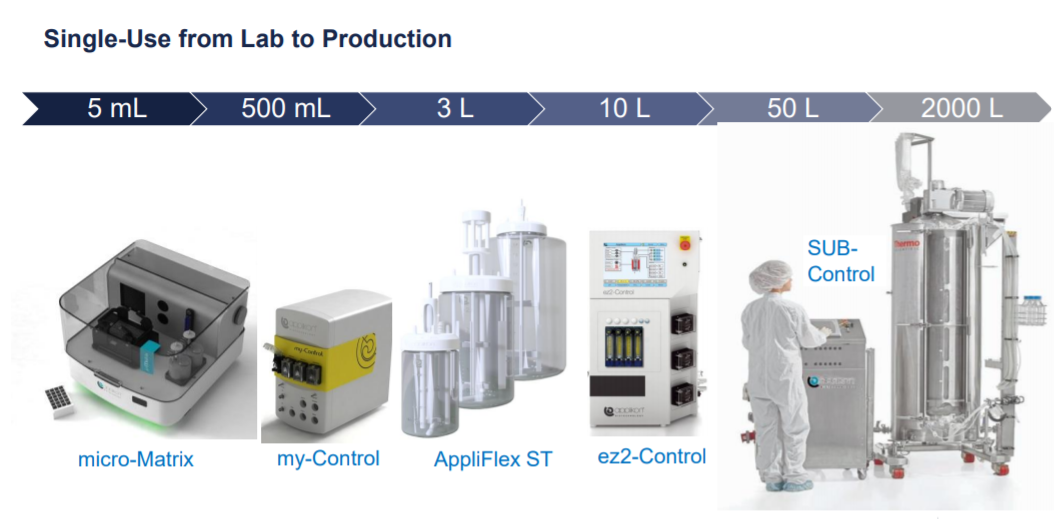

With the AppliFlex ST single-use mini bioreactor, we provide the same flexibility of our customizable range of glass and stainless-steel bioreactor systems to the single-use lab scale bioreactor market. Applikon offers tailor-made and fully reproducible solutions with 500 mL and 3 L single-use bioreactors. By using 3D printing technology, we can create any bioreactor configuration that optimally accommodates your process requirements.

Applications

Fully customizable single-use solution

The single-use design offers a fast start-up of your process. The system is supplied gamma radiated and ready to go with all tubing and connections. The risk of cross contamination between runs belongs to the past and time-consuming cleaning is no longer needed since the system will be disposed of after usage.

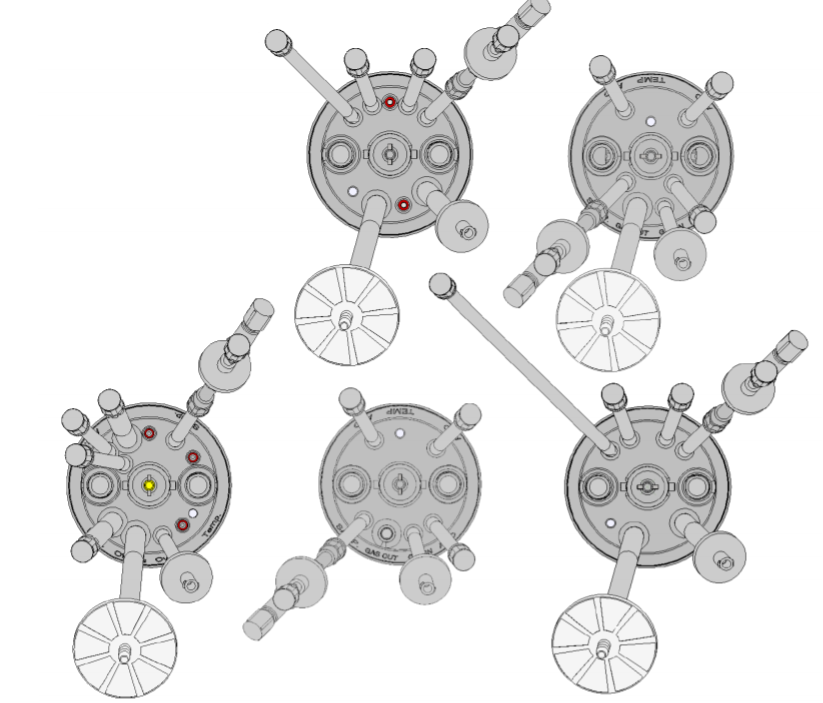

The AppliFlex ST differentiates from other single-use bioreactors by being a fully customizable stirred tank bioreactor. You can choose, or even design, the type and number of impellers, the number of liquid and gas additions and the type of sparger to create a bioreactor that is designed for your process. No more unused ports with blindplugs, but an optimized bioreactor for your specific process development and R&D application.

Typical upstream bioprocessing optimization concentrates on media and strain optimization. The AppliFlex ST enters in a new area of upstream Bioprocess hardware optimization. The Custom AppliFlex ST allows for optimization of essential parameters on a small scale such as impeller and sparger configuration. This technology allows you to optimize your bioreactor and thus maximizes the product yield of your bioprocess.

The 3D printing production technology guarantees complete reproducibility between the different bioreactors guaranteeing exact and identical conditions between runs. The AppliFlex ST offers the flexibility that you need for your specific bioprocess and is available for both cell culture (500 mL and 3 L) and microbial applications (500 mL).

The AppliFlex ST uses the advanced Applikon my-Control for process parameter control offering virtually unlimited control options for this single use mini bioreactor. Standard options are Mass flow control for gas supply, connection of balances for gravimetric feed or harvest and of course our auto tuning adaptive control to guarantee optimal process control independent of changing process conditions.

The AppliFlex ST can easily be integrated in a DeltaV control installation using our V-Control software. This makes process transfer from the lab to production and from production to the lab very simple.

Autosampling

The AppliFlex ST works with autosamplers (like Flownamics and MAST) to easily connect analytical devices and automate the sample processing. To further enhance the integration of analytical data our Lucullus® Process Information Management Software allows complete integration of all devices in the laboratory. Lucullus offers complete workflow management from Design of Experiments and media kitchen mangement up to advanced data processing and reporting.

Unique reactor features

The AppliFlex ST features a fully removable topplate, this allows operators to have easy access to the culture. Pouring into downstream processing vessels or other bioreactors has never been this easy. Optionally a closed lid is available which makes the vessel ready for transport, storage or freezing.

Water supply is not required to operate the AppliFlex ST, cooling and heating are done using electric elements, the condenser is cooled electrically as well. The AppliFlex ST combined with the Applikon my-Control is a very compact bioreactor system. A meter of bench space can fit up to 4 systems. As the AppliFlex ST bioreactor is a closed system, no expensive laminar flowhood is needed to operate the system, except for operator handling.