Based on 40 years of experience in liquid chromatography (LC) technology, the Nexera LC-40 lite Modular HPLC series is a family of HPLC systems that can operate at high performance up to 440 bar, combining AI (Artificial Intelligence) and IoT (Internet of Things) developments.

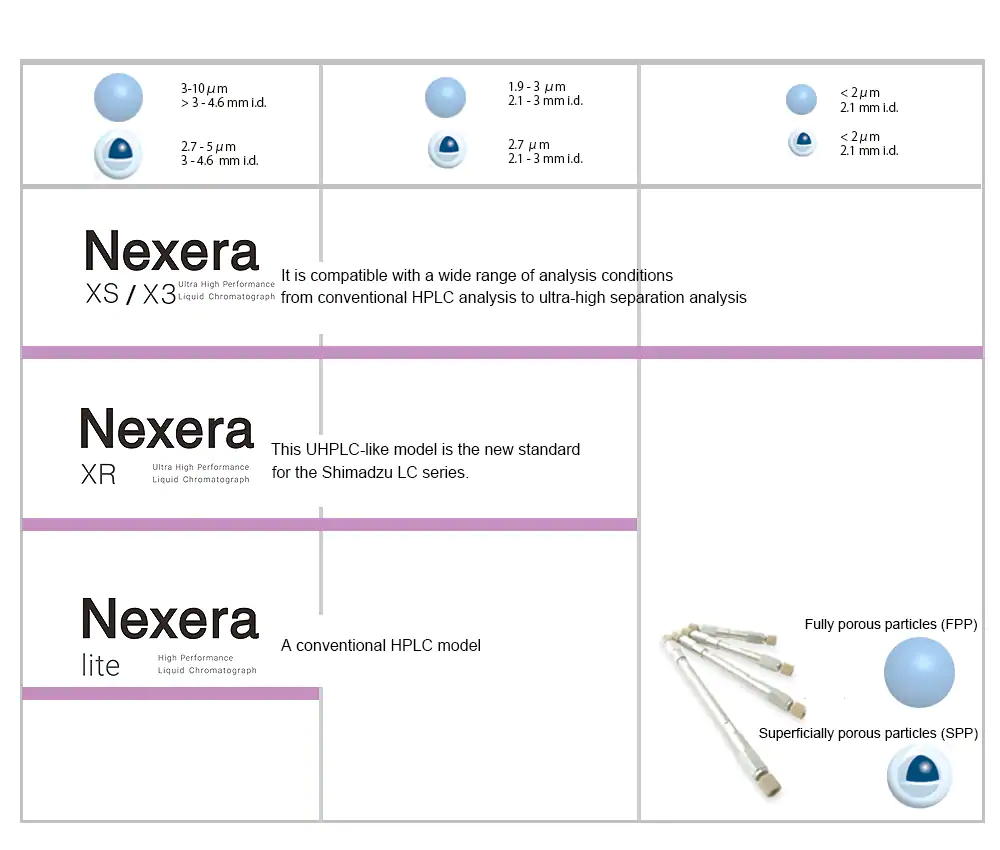

The Shimadzu Nexera series includes the Nexera XS/X3, UHPLC-like model Nexera XR and the conventional HPLC model Nexera lite, which are compatible with many different analysis conditions, from conventional HPLC analysis to ultra-high discrimination analysis.

Some Applications

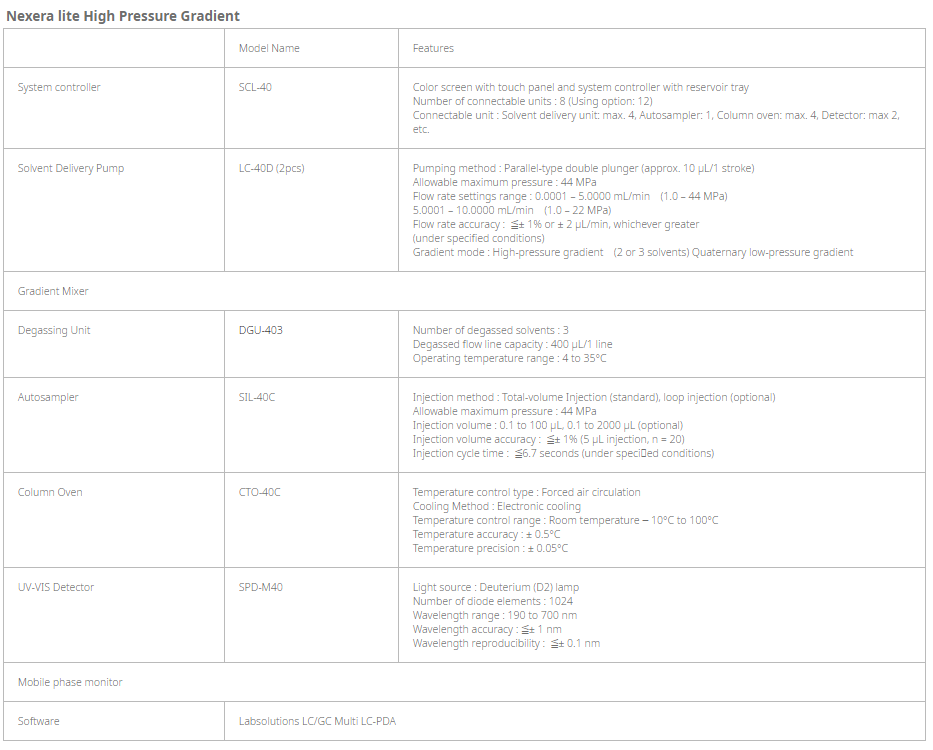

Nexera can be set to start up at a specified time, so that it can complete auto-purge, equilibration and baseline checks in advance, and be ready for analysis as soon as you arrive at the lab. Moreover, the system can be set up in advance to run without user intervention all the way from start up through analysis to shutdown.

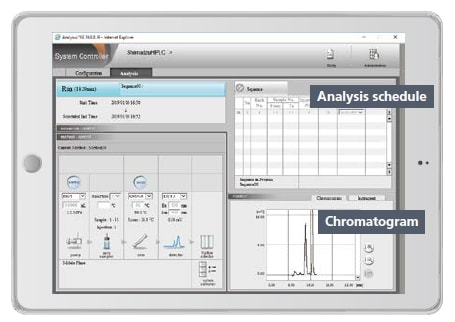

You can view the status and predicted analysis completion time for multiple systems from any location via a smart device. None of these features requires any special software.

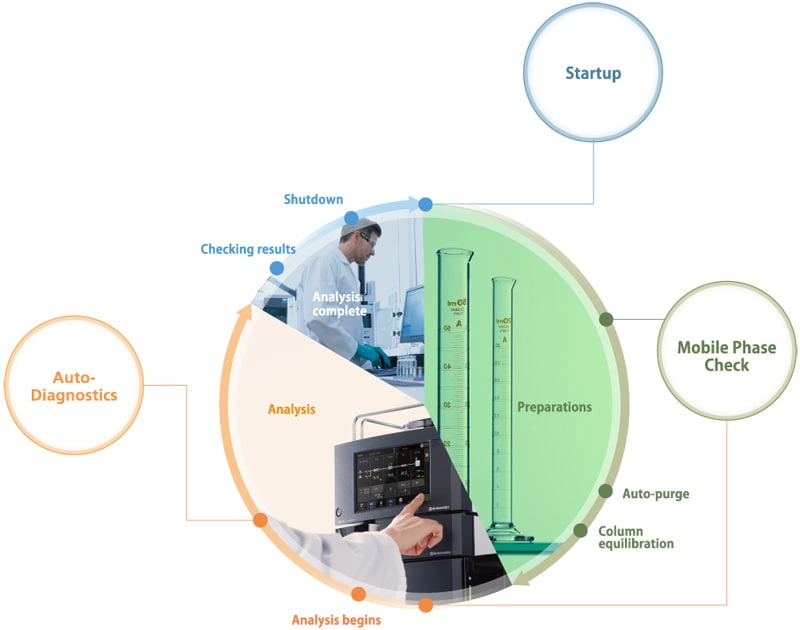

(1) Absorbance Detector SPD-40 / SPD-40V and Photodiode Array Detector SPD-M40

(2) Solvent Delivery Unit LC-40 Series

(3) Autosampler SIL-40 Series / PLATE CHANGER

(4) Mobile Phase Monitor MPM-40

(5) System Controller SCL-40, CBM-40

Discover the efficient LC-40D pump for routine HPLC chromatography applications up to 44 MPa (440 bar). Easy to use and economically designed, the LC-40D pump provides reliable HPLC chromatography in isocratic, binary or LPGE modes. The dual-piston design has minimal vibration for stable baselines. Optional solvent selection valves can be added for solvent selection, low pressure gradient (LPGE) generation and mixing functions.

In rare cases, air bubbles can form in the mobile phase and cause problems if inhaled into the pump. Nexera has the ability to monitor baseline changes and pressure fluctuations to check for abnormalities.

When it detects an unusual fluctuation, it can automatically pause the analysis, purge the flow path, and restart analysis once it has confirmed recovery to normal pressure.

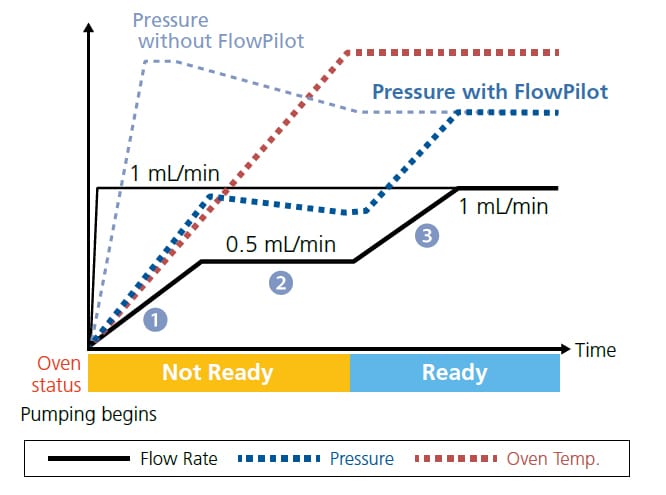

HPLC columns can be damaged by sudden pump starts and stops or extreme gradient changes. The Nexera automatically uses FlowPilot (Smart Flow Control) to increase the flow rate gradually to the set point. There is no need to create startup protocols for each analysis.

Reservoir tray weight sensors (optional) can be used to monitor the volume of mobile phase or autosampler rinse solution in up to twelve containers. The containers can also be checked remotely from a smart device.

You will no longer need to worry about running out of mobile phase mid-analysis, because the device will notify you before starting the run if the volume remaining is too low.

Columns used in analysis need to be traceable to investigate any influence they may have on results. With the Column Management Device (optional), each column is recognized by an individual ID, and stats such as pressure and injection number are automatically recorded in the database and linked to each measurement data file. The device can be linked to all columns regardless of their brand or type. The condition of a column can be checked directly with the column management software, so that you can start analysis without having to test column performance in advance. *To make use of this feature, a CMD compatible with the Nexera series and LabSolutions DB/CS are required.

View the operating status of instruments from a web browser using a smart device. This allows you to confirm parameters such as oven temperature and pump status directly from the web, and to monitor chromatograms in real time without returning to the lab. In addition, SHIMADZU LabTotal™ Smart Service Net (optional) saves operating data from your instruments in a cloud server. Error information, including the date and time the errors occurred, can be sent via email.

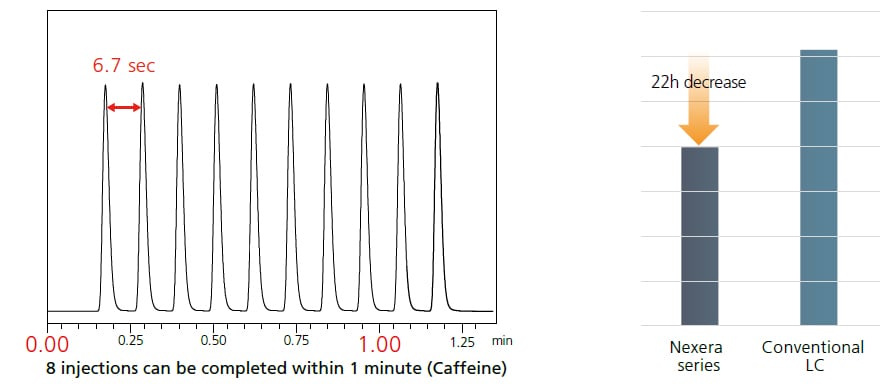

The SIL-40 autosampler can process the entire injection cycle time in as little as seven seconds, twice as fast as the previous model. In addition, continuous analysis can be carried out on up to 44 MTPs (using 3 PLATE CHANGERS). Together these features dramatically increase analysis throughput.

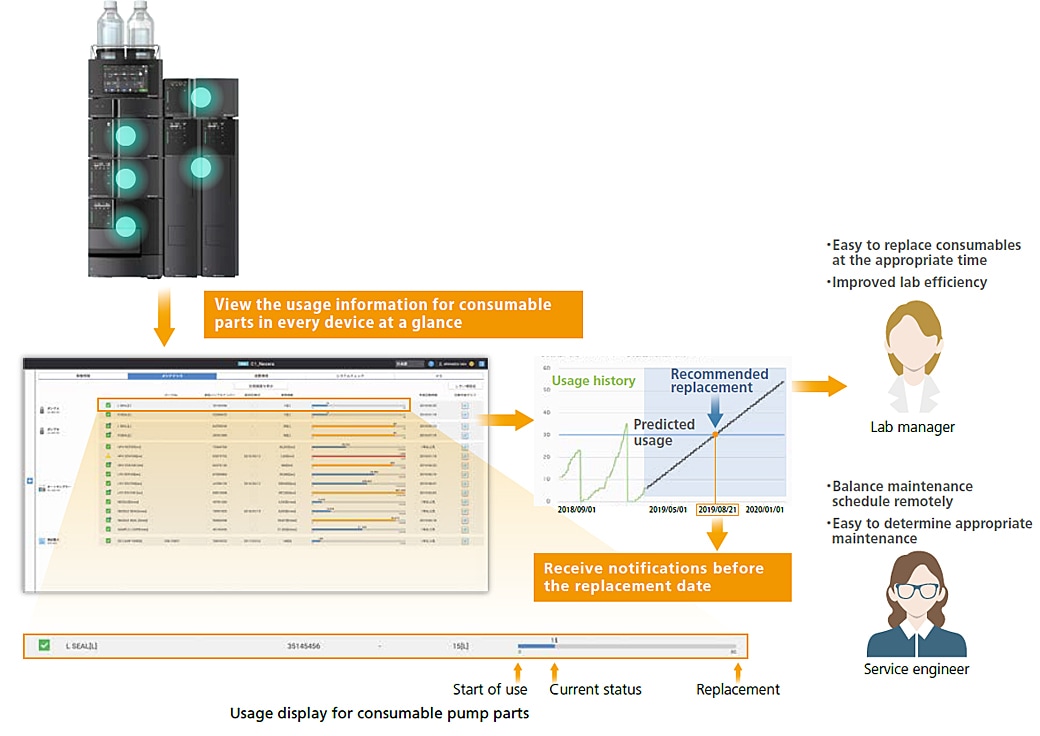

Each Nexera component automatically transfers the status of consumable parts, the traceability information of consumable parts after shipment from the factory, and various logs and error information to the SHIMADZU LabTotal Smart Service Net cloud system. Using this information, the system recommends the timing for consumable part replacement. Problems can be diagnosed remotely by Shimadzu service engineers. This means the system can be maintained in optimal condition and equipment management costs can also be reduced.

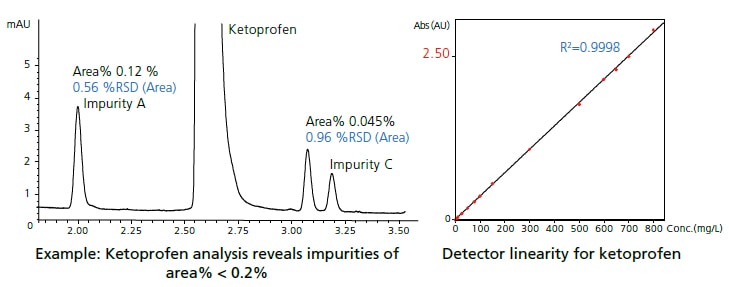

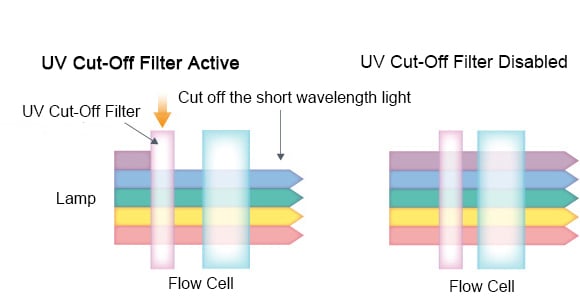

The SPD-M40 detector achieves an extremely high level of sensitivity and linearity (up to 2.5 AU). This allows quantitation of very lowconcentration impurities even in high-concentration samples. The UV cut-off filter installed in the detector prevents sample degradation due to UV light, helping to maintain good linearity at low concentrations.

The UV cut-off filter resulted to be useful for quantitative determination of components that are easily degraded by wavelengths in the UV range, particularly improving quantitation accuracy in the low concentration range.

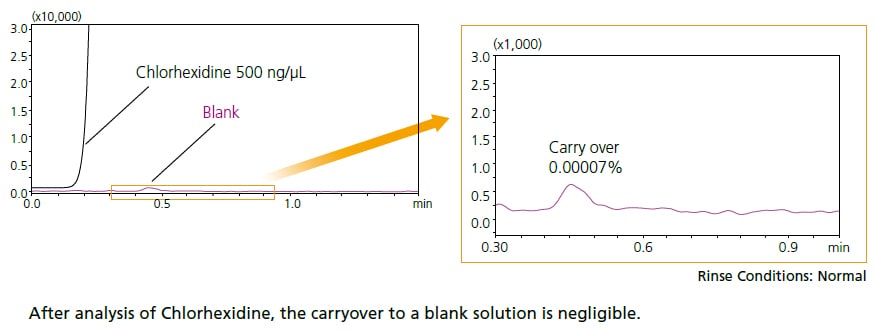

The Nexera boasts ultra-low carryover, even on a high-sensitivity LC/MS/MS. This reduces time spent on rinsing, resulting in a shorter overall analysis time.

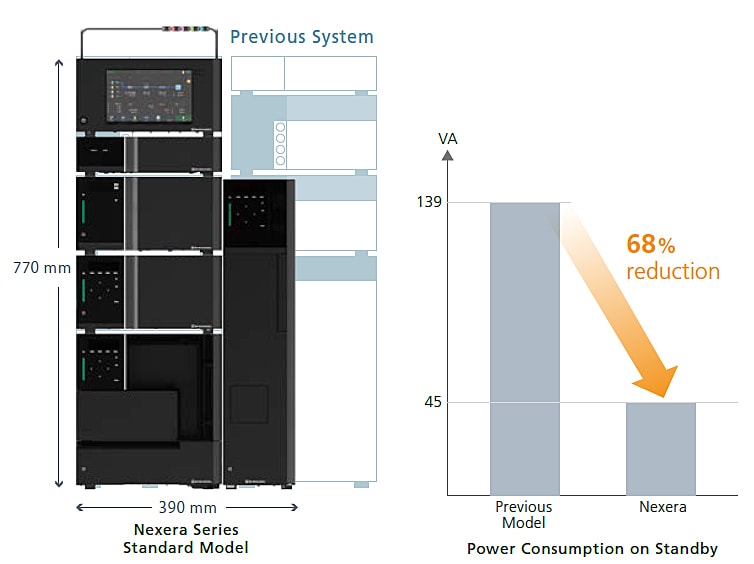

The Nexera frees up bench space with a compact design two thirds the size of Shimadzu's previous model.

The Nexera uses over 80% less electricity when in standby mode, significantly reducing running costs and supporting an environmentally-friendly lab

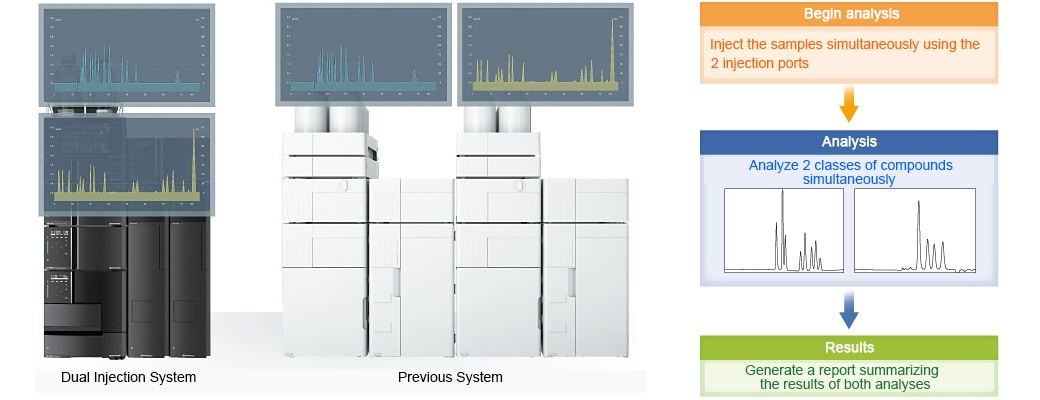

Injection ports for two separate flow paths can be installed, allowing two different types of analysis (such as analysis of amino acids, organic acids or vitamins) to be performed using one system.

The large LCD touch panel on the SCL-40 system controller removes the need for a PC. As well as controlling the instrument and checking the analysis status, you can monitor chromatograms directly from the display. Note: If you prefer to link the system to a PC, the touch panel feature can be turned off. Please inform the service staff during system installation.

Automated support functions using digital technology such as M2M, IoT and Artificial Intelligence (AI), providing higher productivity and maximum reliability.

It allows a system to monitor and diagnose itself, handle any issues during data collection without user input, and automatically pretend to be run by an expert.

It supports the capture of high quality, reproducible data regardless of operator skill level for both routine and demanding applications.