Bioreactors and fermenters are excellent in quality and modularity.

An Applikon laboratory system is easy to upgrade in case of a change in research activities. Applikon offers glass autoclavable bioreactors for cell culture applications and glass autoclavable fermenters for microbial culture applications.

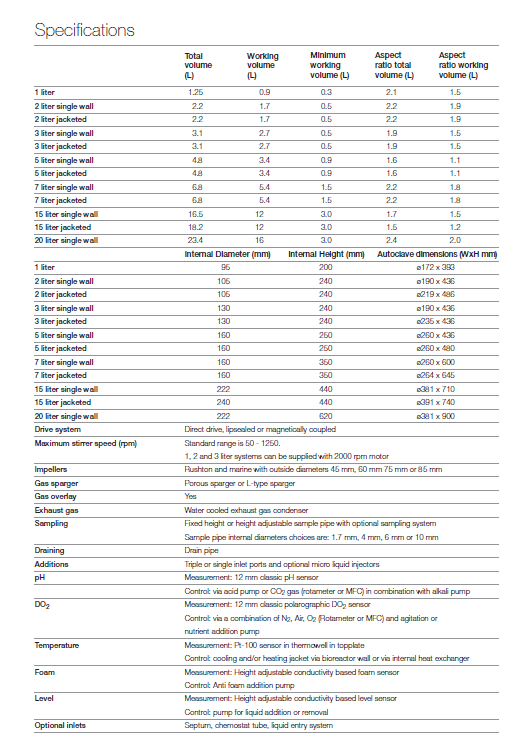

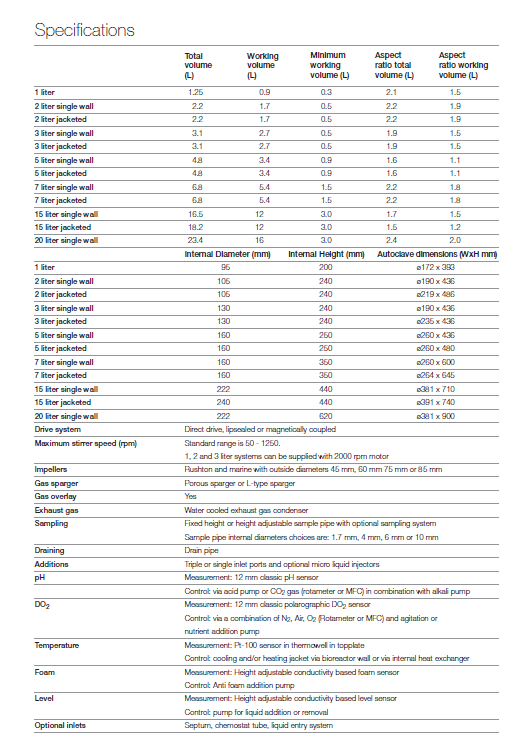

Systems are built to the specific demands of a process using a comprehensive set of standard components. Due to the modularity and flexibility the user can always adapt the systems to the changing process demands. This results in low initial investment and low operating costs. The stirred tank reactor (STR) is the most widely used type of bioreactor. Glass autoclavable bioreactors and fermenters are available in 1 - 2 - 3 - 5 - 7 - 15 and 20 liters total volume.

- A wide range of volumes with interchangeable modules

- A wide range of modules to tailor the systems to the research demands

- No welded parts in the bioreactor top plate

- Simple set-up and easy to handle

- Optional high torque magnetically coupled agitator

- All metal parts are constructed of stainless steel 316L

- The electropolished finish of product contact stainless steel parts ease cleanability

- Glass dished bottom vessels are made of borosilicate glass to guarantee: resistance to thermal shock, excellent corrosion resistance, smooth, non-porous surface for easy cleaning, optimal transparency for visual inspection of the culture

- Glass bioreactor vessels can be used up to 0.5 bar (7.5 psi) of overpressure.

In order to ensure the most efficient level, the devices have functions such as proper sterility that prevents contamination, optimal mixing process with low-uniform shear, adequate mass (oxygen) transfer, precise heat transfer, long-term stability, preservation of monoseptic conditions at all times during the fermentation stage, anti-foaming system. It has been designed in accordance with user needs.

At the same time, the ability to work starting from a small volume provides the user with the opportunity to scale.

The reproducibility of your work relies on a properly cleaned and sterilized bioreactor.

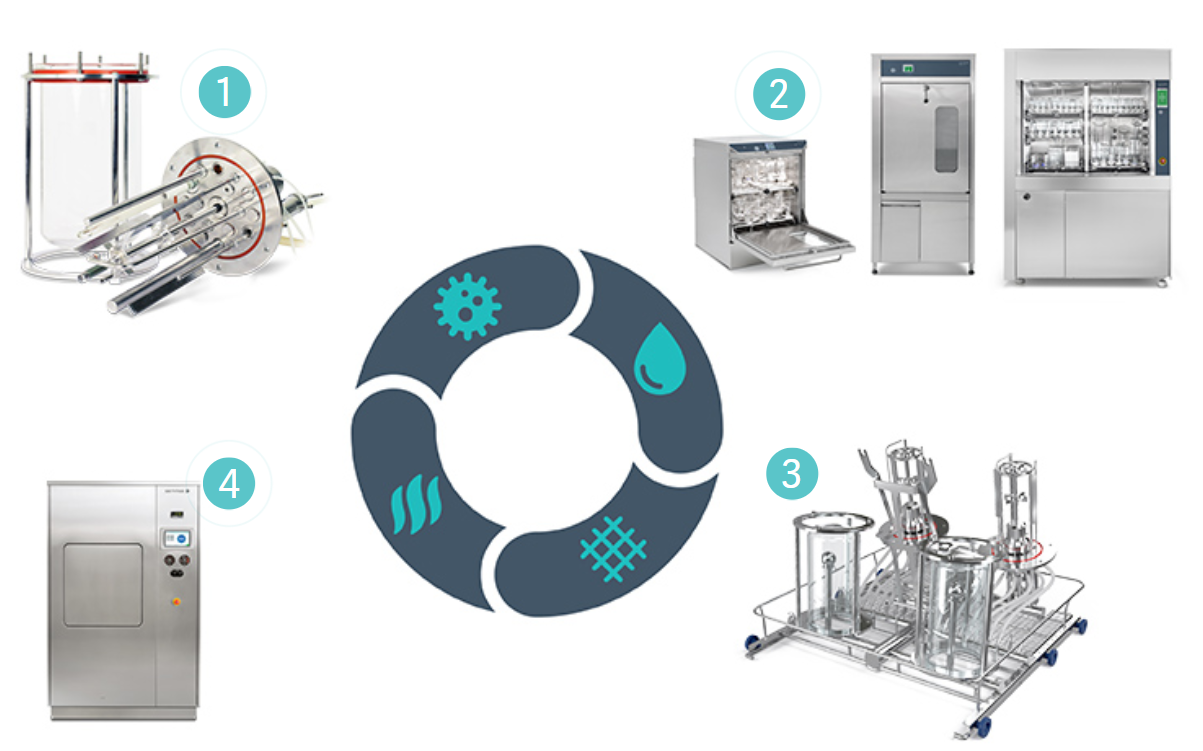

Getinge’s holistic approach to cleaning and sterilization of multi-use bioreactors ensures efficacy and repeatability.

- Automated washing using the purpose-built bioreactor wash rack sets the foundation for a highly reproducible system.

- Getinge’s integrated sterilization process allows three different types of loads in one cycle with ensured steam penetration into all components for improved quality assurance.

Together, the Getinge complete solution confirms accurate, repeatable results in less time with less labor so you can get back to what matters – your work.

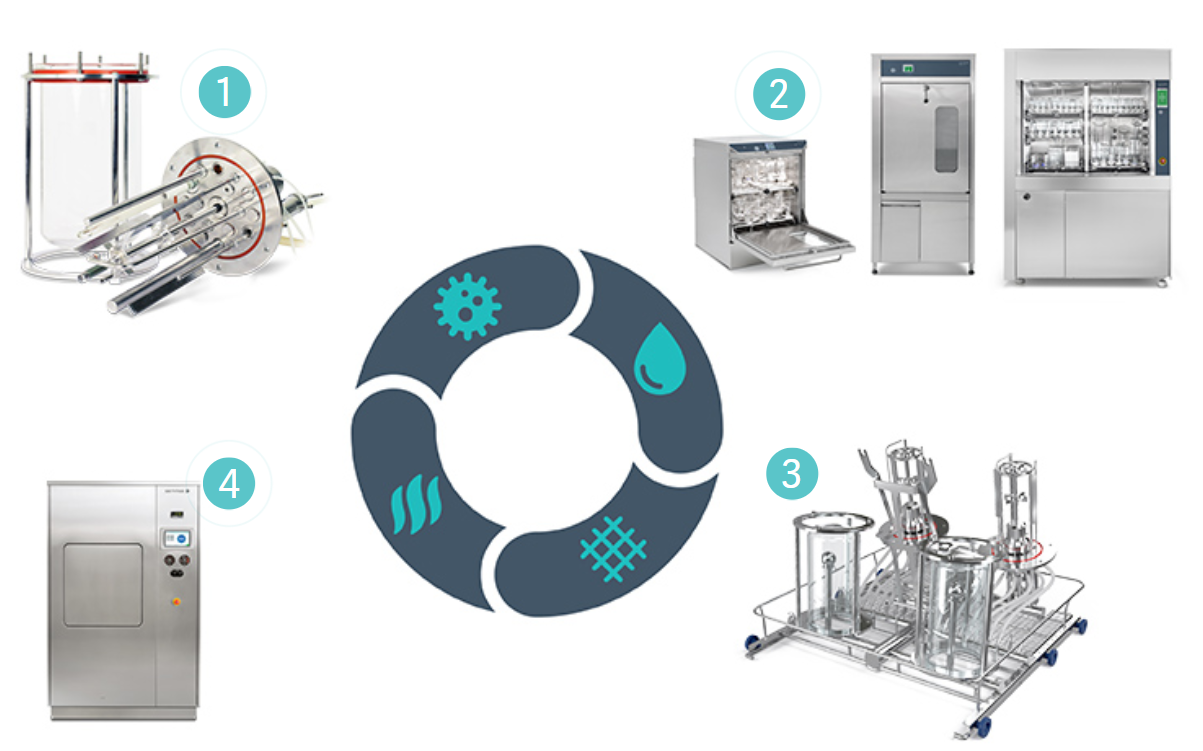

Step 1: Applikon Bioreactor Systems

The Applikon multi-use bioreactor is used in academic, government and biopharmaceutical laboratories for benchtop research.

- Glass autoclavable bioreactors and fermenters are available in 2, 3, 5, 7, 15, and 20L (0.5gal to 5gal) total volume

Step 2: Getinge Lancer Ultima Laboratory Washers

The Getinge Lancer Ultima series includes undercounter and freestanding models that offer a wide range of labware loading options depending on the research being made.

- Programmable labware washer establishes a highly reproducible system, reduces labor, increases throughput and minimizes downtime.

- Getinge Lancer Ultima Series models are available in sizes ranging from 140L to 528L (4.9 cu.ft. to 18.7 cu.ft.).

Step 3: Getinge Laboratory Sterilizers

Getinge GSS L/-R and Getinge Lancer LSS Sterilizers offer the simplest solution to assured sterilization for reproducibility and quality assurance.

- Accommodates three different types of loads, hard goods, tubing and liquid, in one cycle while removing all ambient air using a single pre-vacuum and multi-pulsed steam pressure.

- Getinge Laboratory Sterilizers includes models in sizes ranging from 130L to 1000L (4.6 cu.ft. to 35.3 cu.ft.).

Step 4: Getinge Bioreactor Wash Rack

When Getinge washers include the Getinge specialty wash rack, the Applikon multi-use bioreactor can be partially or fully disassembled before washing.

- The design features an injector system to clean ports on the bioreactor headplate.

- Pre-validated cleaning performance ensures accurate and repeatable results

6 important steps in the cleaning and sterilization process

- Determine if Repeat or New Process

- Disassembly and Washing Prep

- Rack Loading, Washing and Reassembly

- Preparation for Sterilization

- Sterilization

- Return to Service

A programmable labware washer with specialty multi-use bioreactor rack assures thorough cleaning, better reproducibility and reduced labor.

The Solution

The combination of pre-validated washing and sterilization performed in the washer and sterilizer maintain an approved standard for quality control that reduces the chance of human error or deviation from proven process.

With the Applikon e-learning system, the user can easily access many usage processes such as stages, data and tables that he/she wants to see and learn from the internet and work with the most accurate efficiency in the shortest time. With the Applikon Academy Training Program, the user has the opportunity to see and learn the stages of the bioreactor closely where it is produced.

Best Practices for Multi-Use Bioreactor Sterilization

Regardless of whether the bioreactor is prepared for the same use application or for a completely different application, all bioreactor components and liquid media must be prepared through an efficient and repeatable process.

Sterilization Process

Sterilization Process

Regardless of the operating mode, the autoclave must meet the minimum temperature plateau of 121°C with a minimum dwell time of 20 minutes to ensure the effectiveness of the sterilization cycle.

3 Test Types and 3 Sterilization Methods

Standard Test Cycle

Steam injection heats up to 121°C for a minimum of 20 minutes

Pre Vacuum

Pre-vacuum is added to increase air evacuation and improve steam penetration in the vessel and pipe

Pre-Vacuum and Pressure Pulses

The pre-vacuum is followed by pulses of vapor pressure to remove residual air and ensure maximum vapor penetration in vessels and pipes.

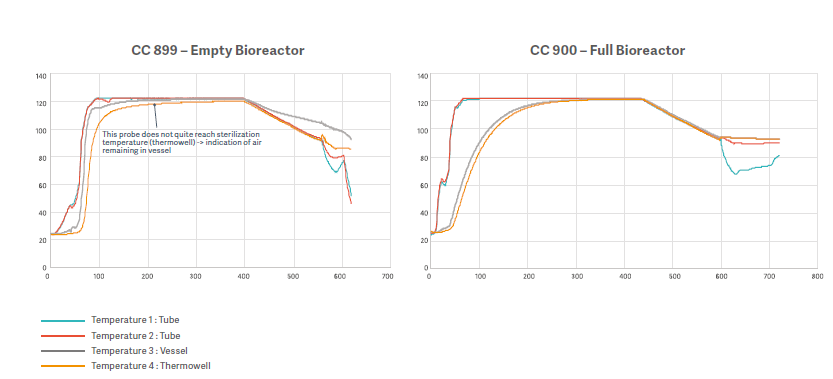

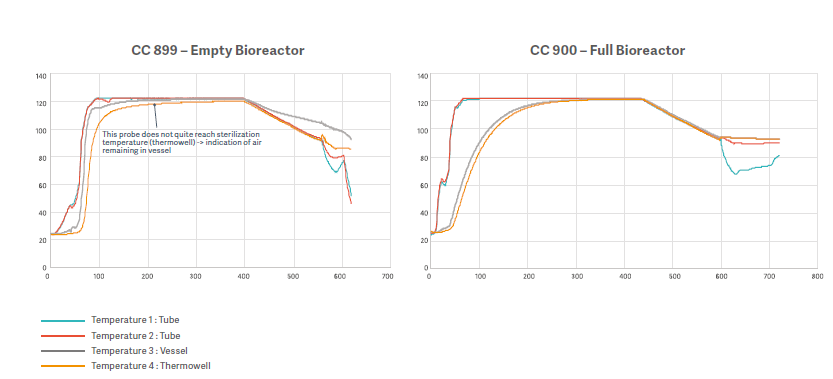

Empty and Full Bioreactor

A test was conducted at the Getinge Sterilization Testing Laboratory to evaluate the effectiveness of the extended waiting time.

The test compared the results of a 40 min dwell time in an empty bioreactor (CC 899) with a 3L container full 2.4L (CC 900) for the same dwell time.

In the CC 899, the temperature sensor inserted in the thermowell did not reach 121°C even after 40 minutes.

However, the bioindicator test results did not show bacterial growth, confirming that the extended plateau time improved sterilization results.

In the CC 900, the extended plateau time and the reduced liquid in the vessel allowed the minimum temperature to be reached throughout. Bioindicator results also confirmed sterilization in this scenario.

In the CC 900, the extended plateau time and the reduced liquid in the vessel allowed the minimum temperature to be reached throughout. Bioindicator results also confirmed sterilization in this scenario.