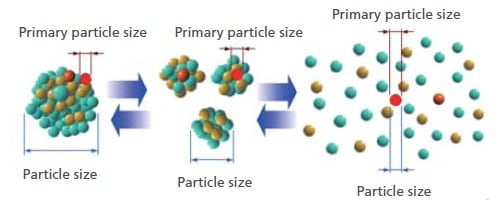

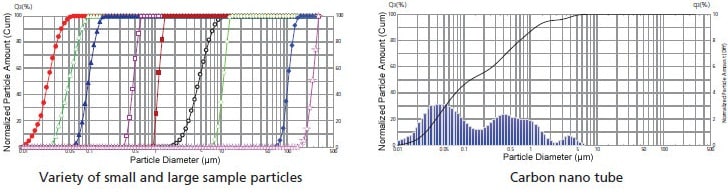

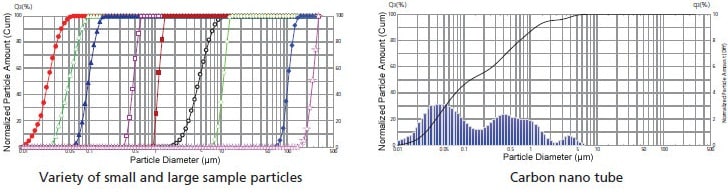

- Changes in particle size across the 7 nm to 800 μm measurement range can be continuously measured using a single light source, single optical system and single measurement principle.

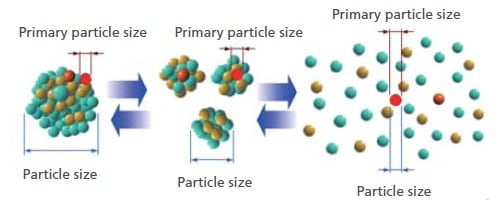

- Since a primary particle and an aggregate and contaminant can be measured with one system, the aggregation properties by a dispersion condition can be checked.

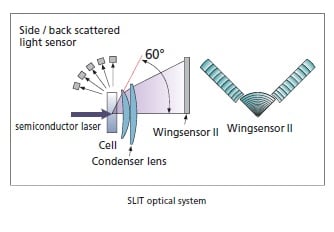

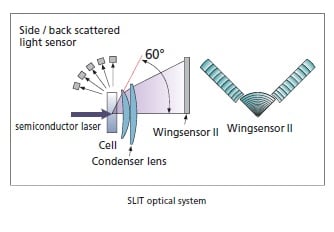

Single detection face continuously captures forward- scattered light up to a 60° angle

The target particle size range is seamlessly covered using a single measurement principle, single optical system, and single light source. Additionally, because the SALD-7500nano Particle Size Analyzer does not incorporate multiple optical systems that create discontinuities in the data, accurate particle size distribution measurements are possible across the entire measurement range using a single standard. The application of the SLIT* optical system, based on sophisticated scattered light intensity tracing technology, smashes conventional wisdom to continuously capture forward-scattered light at up to a wide 60° angle on a single detector face. This achieves high resolution in the fine particle region.

High-Resolution/High-Sensitivity Wing Sensor ll

Forward diffracted/scattered light is detected by a “wing sensor ll”, a 76-element sensor developed using semiconductor manufacturing technology of the highest level. This sensor can detect greatly fluctuating small-angle forward scattering light with a high level of resolution and wide-angle scattering light of a low optical intensity with a high level of sensitivity. Also, side scattered light is detected by one sensor element and back scattered light is detected by four sensor elements. Accurately capturing light intensity distribution patterns with a total of 81 sensor elements enables the high-resolution, high-precision measurement of particle size distributions over a wide particle diameter range.

More Stable Optical System

The Omnidirectional Shock Absorption Frame (OSAF) fully isolates all elements of the optical system from shocks and vibrations. This eliminates concerns about adjusting the optical axis.

Built-in Self-Diagnostic Functions Ensure Easy Maintenance

These analyzers incorporate powerful self-diagnostic functions. The output signals sent by the sensors and detecting elements and the instrument operating status can be checked, facilitating easier maintenance. Using the Operation Log function, detailed information about, for example, the instrument usage status and contamination of the cells is included with all the measurement data, making it is possible to investigate the validity of measurement data obtained in the past.

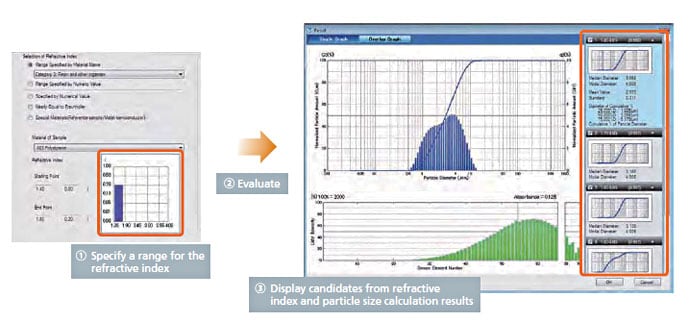

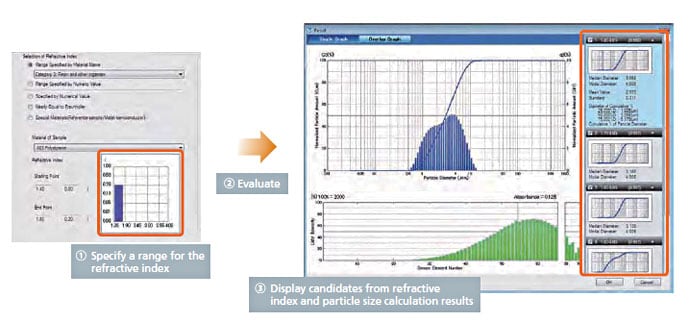

Eliminates the mistake or trouble of selecting refractive indices

Automatic Refractive Index Calculation Function

Selecting a refractive index was an unavoidable part of using the laser diffraction method, where generally a published value was entered, but such values were not necessarily appropriate, considering the effects of particle composition and shape. Therefore, tedious trial and error processes were used to select refractive indices.

WingSALD II solves such problems by being the world's first software to include a function that automatically calculates an appropriate refractive index based on the LDR (light intensity distribution reproduction) method.

Wide application applicability

The system configuration can be optimized to address various uses, purposes, measurement objects, environments and conditions.

Laser diffraction method ISO 13320 and JIS Z 8825-1 compliant

Tke SALD-7500nano complies with ISO 13320 and JIS Z 8825-1 laser diffraction and scattering standards.

Validation possible with JIS standard particles

System performances can be confirmed using a MBP1-10 standard particle specified in JIS Z8900-1. These samples have a broad particle size distribution, which is specified by the JIS standard. Using these samples allows verifying that the instrument is always accurate.

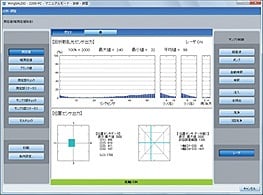

Allows verifying the validity of measurement results by referencing light intensity distribution data

Since light intensity distribution data (raw data) and measurement results (particle size distribution data) can be displayed on the same screen, measurement results can be verified while viewing both data sets. This allows users to verify whether the detection signal level (particle concentration) is appropriate, and to confirm the validity of measurement results from multiple aspects, such as in terms of the distribution width and the presence of aggregates and contaminants.

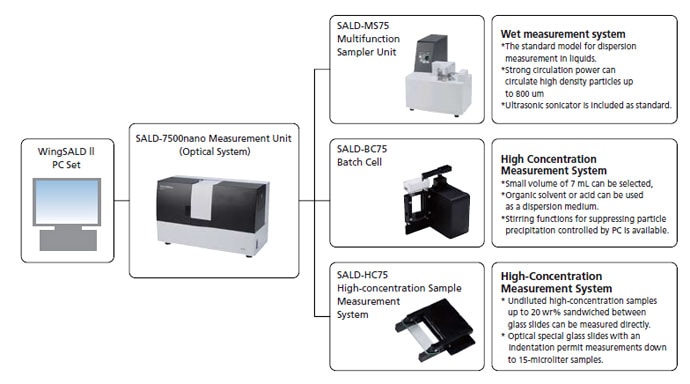

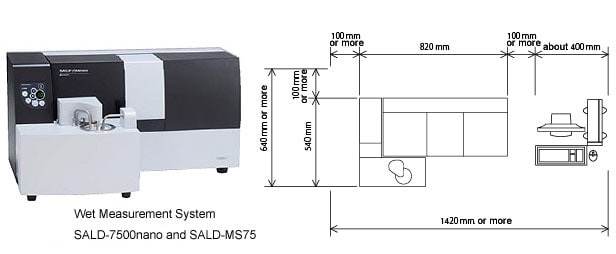

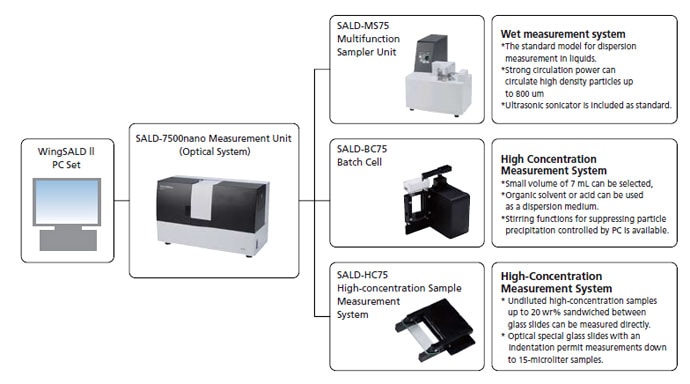

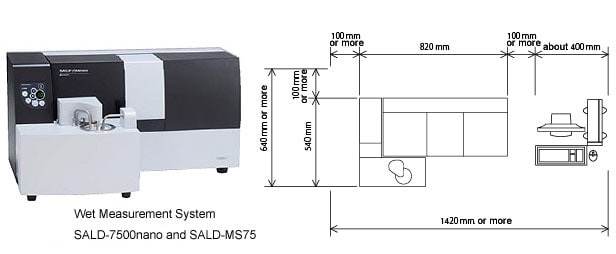

System Structure

An evolved nano particle size analyzer for accurate evaluation of nano particles

Main unit (Measurement unit): SALD-7500nano

- Violet semiconductor laser (wavelength: 405 nm) is used for the light source. Maintenance, such as gas replacement, is unnecessary.

- The detector incorporates 78 elements at the front, one element at the side, and 5 elements at the back for a total of 84 elements. Additionally, high-sensitivity light receptors that support violet semiconductor laser wavelengths are adopted with all detectors.

- The fixed parts of the cell and cell holder can be pulled out at the front of the unit using a slide mechanism. This makes it easy to mount and replace cells, and to perform maintenance.

- WingSALD ll software is supplied as standard. It offers versatile data processing and simple, high-speed operation to suit every purpose and processing requirement.

Add optional units to the SALD-7500nano to design a wide range of systems

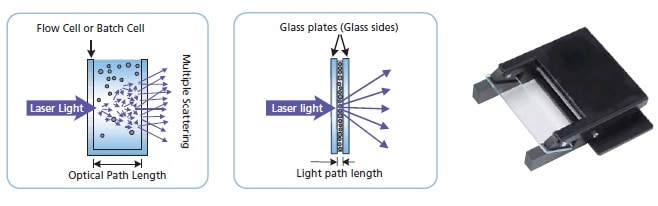

- The batch cell and the high-concentration sample measurement system can be set in the measurement unit.

- Small-volume Measurement System (SALD-7500nano and SALD-BC75)

- High-Concentration Sample Measurement System (SALD-7500nano and SALD-HC75)

- Ultra Small-Volume Measurement System (SALD-7500nano and SALD-HC75 and “Glass Slides with Indentation”)

Easy Measurement under PC Control

- Groups of particles are dispersed in a liquid medium and measured as they are circulated between the flow cell, which is placed in the measurement unit, and a dispersion bath in the sampler.

- The dispersion bath incorporates a stirrer and an ultrasonic sonicator. A pump delivers the dispersed suspension to the flow cell.

- The pump is specially designed to ensure both liquid medium and the particles are circulated. A stainless ball of 2 mm circulates and it is possible to measure it.

- It can be controlled from a PC.

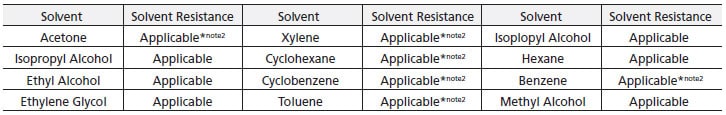

- Most organic solvents can be used as dispersion media.

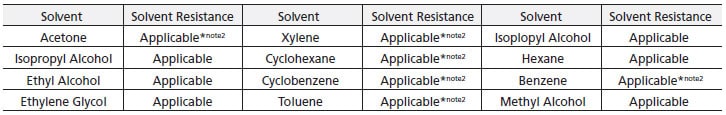

Sample Unit SALD-MS75 Solvent Resistance

Measurement Data

Measurement Samples without Dilution

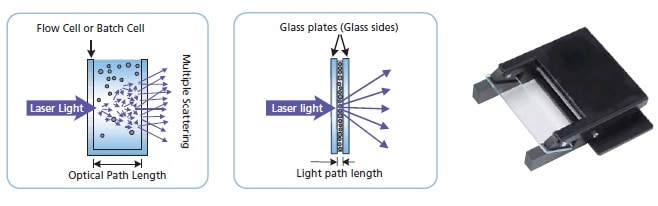

High-Concentration Sample Measurement System: SALD-HC75

- High-concentration samples can be measured using the laser diffraction method.

- Measurement is possible by simply holding the high-concentration sample particles to be measured between two glass slides.

- Samples for which the particle size distribution would be changed by dilution can be measured in their original state, or with the minimum required level of dilution, and a true image of the measurement object can be obtained.

- Commercial hand creams, face creams, and rinses can be measured with hardly any pretreatment.