Scanning Probe Microscope (SPM) is a system that displays the finest details of the sample surface by measuring the atomic force between the two after a very small cantilever is placed on the sample surface. The surface properties of metals, semiconductors, ceramics, organic materials, very high molecular weight polymers and biological samples are examined at a magnification of a million times without the need for sample coating.

Unknown Visible Scanning Probe Microscope (Scanning Probe Microscope) is a general term for microscopes that scan sample surfaces with an extremely sharp probe to observe their three-dimensional images or local features at high magnifications. The SPM-9700HT takes high-throughput observations to the next level.

Due to the new deveopled HT scanner that achieves a high-speed response and optimizing softwares and the design of control system, aquisition of the image data is now available at a speed of conventional than 5 times or more(our ratio). The scanner can easily be replaced so existing scanners can be used. The HT scanner can also be added to an existing SPM-9700 unit to enable high-throughput observation.

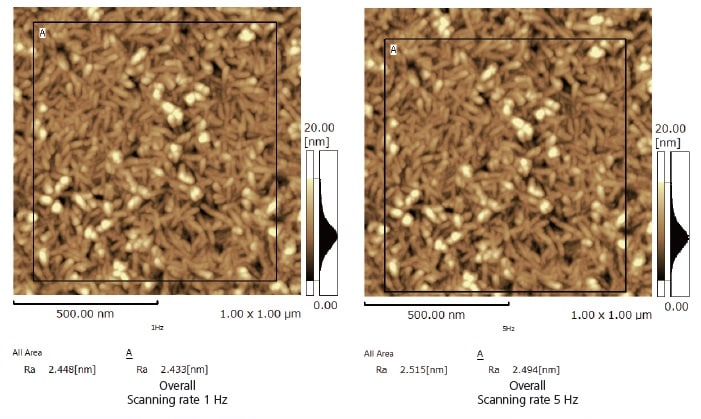

The surface topology of a vapor-deposited metal film was observed using a scanning rate of 1 Hz and 5 Hz.

Image quality and surface roughness analysis results are equivalent.

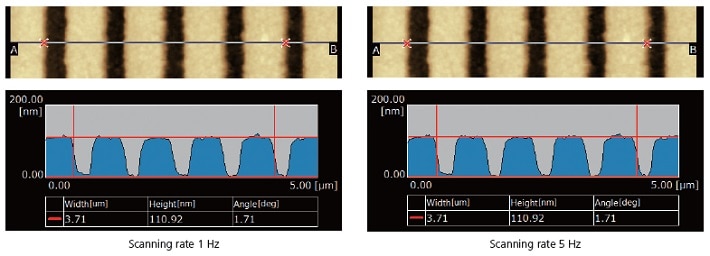

The grating surface topology was observed at a scanning rate of 1 Hz and 5 Hz. The measurement by cross-section profile analysis shows that both give the same results.

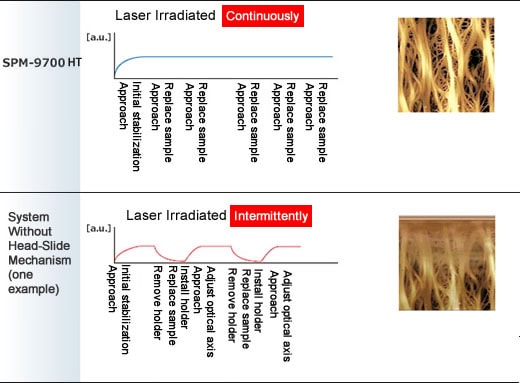

With the optical lever system and cantilever integrated in the head, samples can be replaced by simply sliding the head. Since samples can be changed without shutting off the laser beam, laser irradiation characteristics remain highly stable even after changing the sample. This eliminates the need to readjust the optical axis or other parameters associated with stopping the laser, which means analysis times can be shortened.

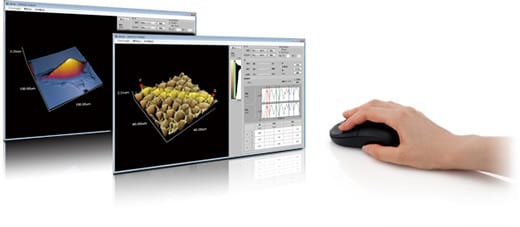

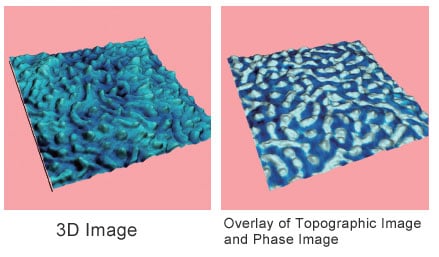

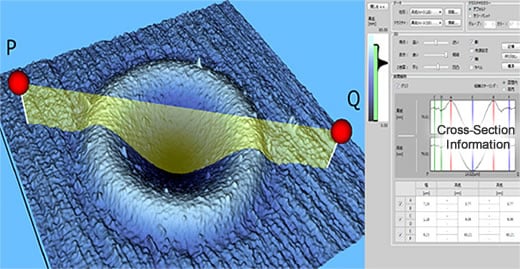

Images can be freely rotated, zoomed, and Z-axis magnification varied using the mouse to intuitively adjust the viewing angle or magnification level. Using sophisticated analytical tools, such as a texture function, which displays sample physical properties overlaid with height information, or a 3D cross-section profile analysis function, dramatically improves the efficiency of image verification work.

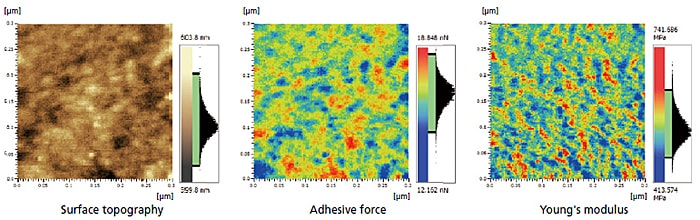

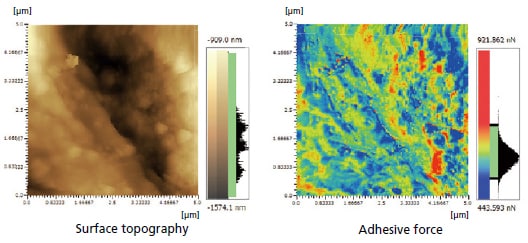

Height information can be displayed overlaid with information about other physical properties. This allows clearly showing the relationship between both parameters.

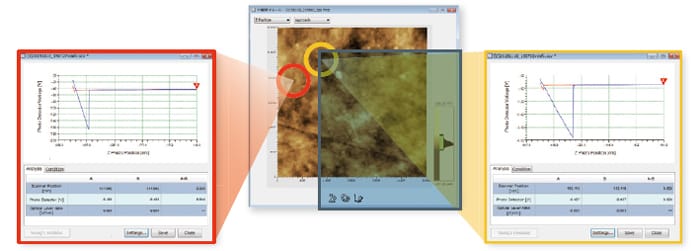

Cross-section profiles can be analyzed in 3D images. If physical property information is expressed in terms of texture, respective cross-section profiles can be displayed and analyzed in the same location.

The physical properties of external or boundary surfaces can be evaluated by measuring the force acting on a

scanning probe microscope cantilever probe as its distance from the sample is varied (force curve measurement).