Shimadzu Triple Quadrupole GCMS-TQ8050 NX Gas Chromatography Mass Spectrometer can perform unprecedented quantitative GC-MS/MS analyzes of ultra-trace amounts down to the femtogram level. Equipped with a new, highly efficient detector and three types of noise reduction technologies, the GCMS-TQ8050 NX has never been more important in the food safety, pharmaceutical, environmental, clinical research, forensics and similar industries.

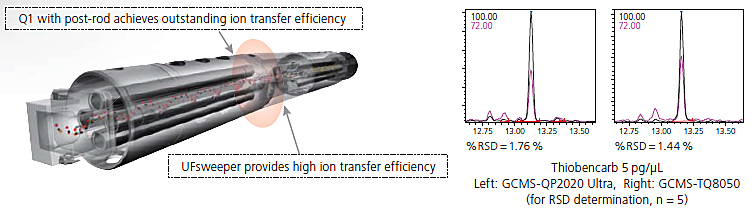

A new chromatography detector with better amplification performance maximizes the benefits of the OFF-AXIS Ion Optics, which offers both high ion transmission performance and outstanding noise elimination performance. These state-of-the-art technologies enable the system to reliably detect ultra trace quantities of ions, down to the femtogram level, achieving the world's highest* sensitivity levels.

In addition to high sensitivity, the gas chromatography mass spectrometry system offers highly robust performance. The contamination-resistant ion source and the new detector with over five times longer service life ensure reliable, long-term analysis. An oil-free pump that can be operated for three years without maintenance is also available.

A new turbomolecular pump with higher evacuation performance achieves a superior vacuum state in the MS unit. This results in higher sensitivity and stability and helps improve analysis accuracy for ultra-trace concentration levels.

Using the ultra-fast analysis technology (UFsweeper) offered in existing models, the system can simultaneously analyze samples using multiple modes, such as high-speed scanning and scan/MRM modes.

The Smart MRM technology that optimizes sensitivity helps accurately create methods for ultra-trace analysis and ensures high sensitivity for MRM measurements.

In addition, the enhanced accuracy control function provided by LabSolutions Insight software improves the reliability of analyzing data acquired from simultaneous multicomponent analysis of ultra-trace components.

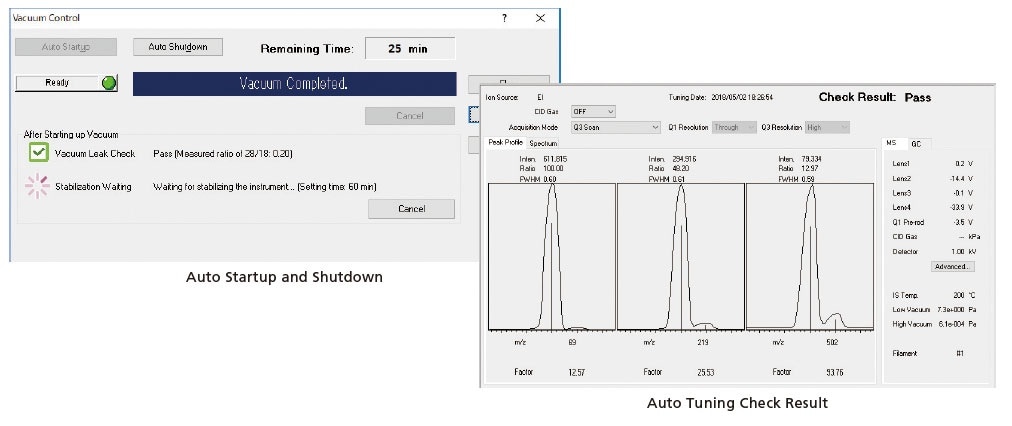

The mass spectrometer (MS) has to be operated in a vacuum condition, the startup and stopping of the system takes time depending on the condition. Determining this can be a challenge. Since the amount of time that the system takes when starting up or stopping is displayed in real time, it is easy to accurately determine when maintenance of the ion source or analysis is possible. Moreover, tasks that until now needed to be performed by the user, such as leak checks upon system startup and auto tuning, are now performed automatically.

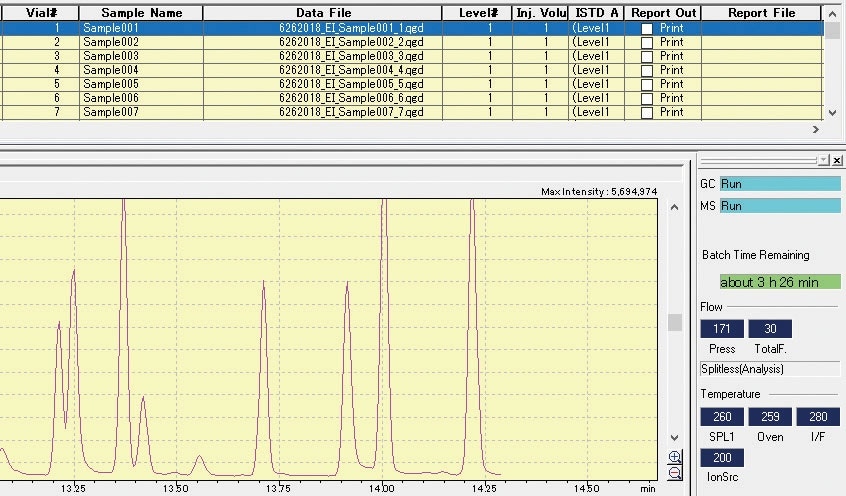

By displaying the time required for continuous analysis in real time, the time when the current continuous analysis will finish can be accurately confirmed. This increases the instrument operating time (active time) by reducing standby time required during continuous analysis or while switching between different users. In addition, because this function makes it easier to schedule the timing for analysis preparations, such as sample preparation and pretreatment, based on the finish time of the previous analysis, it enables analytical processes to be performed more efficiently, which can help improve work-life balance.

The Easy Stop function of gas chromatography mass spectrometry system, used to safely maintain the sample injection port without releasing the vacuum, displays the remaining time (coolingdown time) when the septum or the insert can be replaced in real time. Maintenance time can be minimized by understanding the accurate remaining time.

Furthermore, by using a ClickTek nut on the top of the sample injection port, the port can be opened or closed without tools, by simply using fingers to twist a lever. That enables faster and easier insert replacement than ever before.