XRD-6100 X-Ray Diffractometer, XRD-6100 with high precision θ-2θ (theta/2 theta) goniometer, can be expanded with optional accessories in accordance with the purpose.

In addition to its basic ease of use and rich functionality, the XRD-6100 X-Ray Diffractometer has an integrated design that includes a vertical protractor and data processing software supporting a Windows user interface.

The XRD-6100 offers solutions covering a wide range of analysis needs from routine qualitative and quantitative analysis to state change analysis, including stress analysis, residual austenite quantification, crystallite size/lattice stress, crystallinity calculation, materials analysis via superimposed X-ray diffraction patterns. presents. , advanced material evaluation and sample heating analysis. Of course, crystal structure analysis, including precise lattice constant determination, is also supported.

XRD-7000 X-Ray Diffractometer, XRD-7000 Series X-ray diffractometers have a high precision vertical θ-θ protractor and can process large samples up to W400 × D550 × H400mm.

The strong parallel beam optical system with built-in polycapillary unit is available to further expand the range of application.

XRD-6100 X-ray Diffractometer

The control concentration of mineral dust for working environment measurements is calculated using the following expression. (Revised on April 1, 2005. )

E = 3.0/(0.59Q + 1)(Reference) Pre-revision E = 2.9/(0.22Q + 1)

E: Control concentration mg/m3 Q: Free silicic acid content (%)

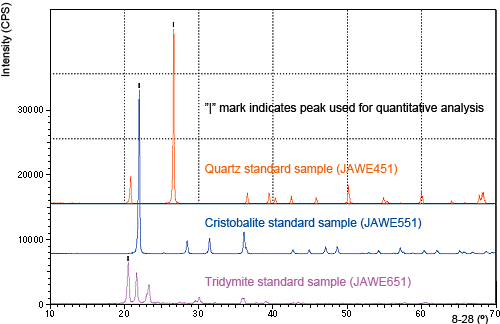

Consequently, it is important to know the content of free silicic acids in the dust. Free silicic acids may be present as quartz, cristobalite, or tridymite, etc.

This revision prescribes the use of an X-ray diffractometer to first identify the type of silicic acid (qualitative analysis). Based on these qualitative results, quantitation is performed using the phosphoric acid method or the base standard absorption correction method with an X-ray diffractometer.

The diagram below shows the diffraction patterns of free silicic acids. The type of free silicic acid can be easily identified from the characteristics of the pattern.

The diffraction X-ray intensity of the target substances must be corrected for the absorption of the matrix substance. This correction requires determination of the X-ray absorption coefficient of the matrix substance. The base standard absorption correction method can determine this from a single measurement. This package includes dedicated quantitative analysis software that incorporates the base standard absorption correction method.

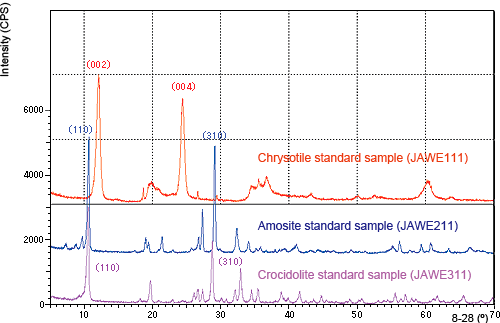

Asbestos Hazard Prevention Regulations were implemented in Japan in July 2005. Building materials and other samples subject to these regulations can be quantified by X-ray diffractometer using the standard addition method or internal standard addition method if the samples contain approximately 5 % or greater asbestos content by weight. If the asbestos content is below 5 %, however, quantitation may not be possible.

In this case, after conducting formic acid pretreatment to dissolve the sample matrix components, quantitation is performed by X-ray diffractometer using the base standard absorption correction method.

Such qualitative and quantitative analysis of asbestos can be performed using the XRD-6100 X-ray diffractometer environmental measurement package, which includes the environmental measurement stage for the base standard absorption correction method.

High precision vertical θ-θ goniometer that can accept up to 400mm (w) x 5500mm (d) x 400mm (h) maximum.

Various application of residual austenite quantitation, environmental quantitative analysis, precise lattice constant determination, degree of crystallinity calculations, crystallite size and crystal strain calculations, crystal system determination, rietveld analysis, other software based crystal structure analysis as well as basic qualitative analysis and quantitative analysis.

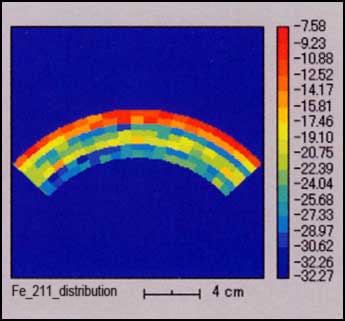

Large R-θ stage can accept sample up to 350 mm diameter and 190 mm thickness. Automatic stress mapping is possible.

Set the sample position on the R-θ stage map and start the analysis to perform the automatic mapping measurements and automatic stress analysis calculations. Separate measurement results can be superimposed. The stress analysis results can be displayed as a map.

The diagram below shows a stress map for a brake rotor. The Fe211 distribution is obvious at a glance.

The powerful parallel beam produced by the polycapillary unit can be used in a wider range applications, such as for uneven samples.(option)

Asbestos is a preferred construction material due to its excellent heat and acid resistance. However, the use of asbestos is gradually limited due to adverse health effects. It is mandatory to follow the asbestos concentration in any construction material according to the limit values specified in the regulations.

In this study, an example of asynchronous analysis of the chrysotile, an asbestos type, is performed using the new wide-range high-speed OneSight detector.

Instrument: Shimadzu XRD-6100/7000