Western Blot Wet, Semi-Dry and Dry Transfer Methods

(Wet Transfer, Semi-Dry Transfer, Dry Transfer)

Efficient and reliable protein transfer from the gel to the blotting membrane is the cornerstone of a successful western detection experiment. The accuracy of the results depends on the transfer efficiency of the western blot method. Traditional wet transfer offers high efficiency, but at the expense of time and effort. Semi-dry drying provides convenience and time savings with the flexibility to use multiple buffer systems or preassembled batches without buffers.

However, semi-dry transfer may have a lower efficiency in transferring large molecular weight proteins (>300 kDa). Dry electroblotting offers high quality transfer with both speed and convenience as no additional buffers are required for dry electroblotting.

Three main ways to manufacture proteins from SDS-PAGE or natural gels to nitrocellulose, PVDF or nylon membranes:

- Wet tank electrotransfer

- Semi-dry electrotransfer

- Dry electrotransfer

Wet Tank Electrotransfer (Wet Tank Transfer)

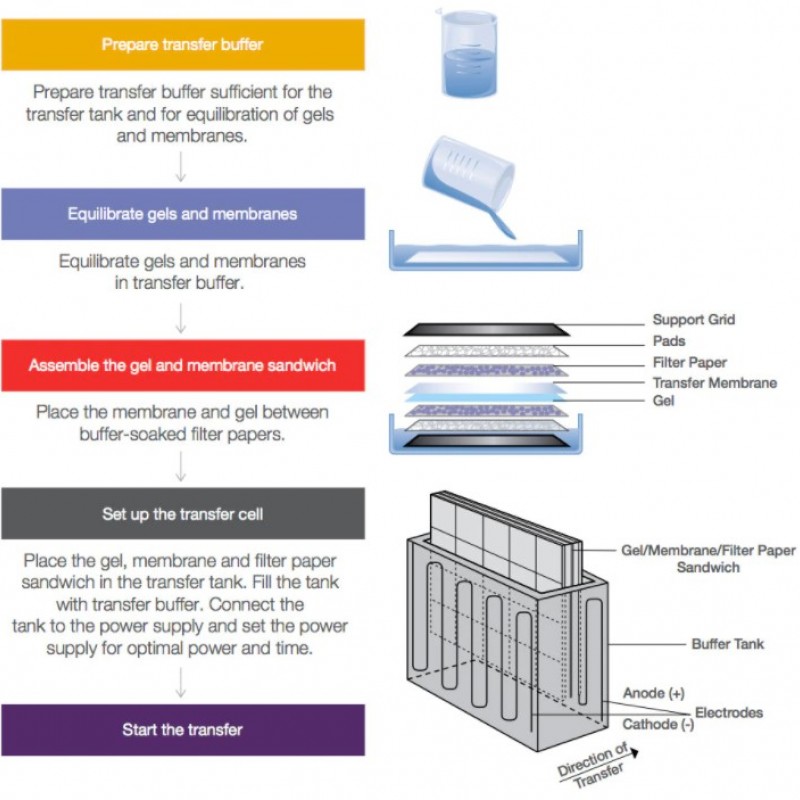

When wet transfer is performed, the gel is first equilibrated in the transfer buffer. The gel is then placed in a "transfer sandwich" (filter paper-gel-membrane-filter paper), padded with pads and pressed together by a support grid. The supported gel sandwich is placed vertically in a tank between the stainless steel/platinum wire electrodes and filled with transfer buffer.

Multiple gels can be electrotransferred in the standard field option, which is performed at constant current (0.1 to 1 A) or voltage (5 to 30 V) for as little as 1 hour to overnight. Transfers are typically performed with an ice pack and at 4°C to reduce the heat generated. A high field option is available that can reduce the transfer time to 30 minutes for a single gel, but requires the use of high voltage (up to 200 V) or high current and a cooling system to dissipate the enormous heat generated.

Tank transfer apparatus for western blotting. Scheme showing the assembly of a typical western blot apparatus with the position of the gel, the transfer membrane, and the protein orientation relative to the electrode position.

Transfer efficiencies of 80-100% can be achieved for proteins between 14-116 kDa. Transfer efficiency increases with increasing transfer time. However, with increasing time, there is a risk of excessive transfer (explosion) of proteins across the membrane, especially for lower molecular weight (<30 kDa) proteins, especially when using membranes with larger pore size (0.45 µm).

Semi-Dry Electrotransfer (Semi-Dry Transfer)

For semi-dry protein transfer, the transfer sandwich is placed horizontally between two plate electrodes in the semi-dry transfer apparatus. Pre-equilibration of the gel in the transfer buffer is essential for this semi-dry transfer. The amount of buffer available during transfer is limited to what is in the sandwich, so it is useful to have extra-thick filter paper (~3 mm thick) and membrane to maximize current through the gel rather than around the gel. also sufficiently wetted in the buffer. Likewise, it is important to cut the filter paper sheets and membrane to gel size.

One to four gels can be rapidly electroblotted onto membranes. Methanol may be included in the transfer buffer, but other organic solvents, including aromatic hydrocarbons, chlorinated hydrocarbons, and acetone, should not be used to avoid damaging the semi-dry blotter. Electrotransfer is performed at constant current (0.1 to ~0.4 A) or voltage (10 to 25 V) for 10 to 60 minutes. To reduce transfer time to 7 to 10 minutes, methanol-free transfer buffers are recommended. Transfer efficiencies of 60% to 80% can be achieved for proteins between 14 and 116 kDa, longer transfer times are required to transfer higher molecular weight proteins.

Semi-dry electroblotting transfer. The Invitrogen Power Blotter is specifically designed for rapid semi-dry transfer of 10-300 kDa proteins from polyacrylamide gels to nitrocellulose or PVDF membranes in 5-10 minutes. The Power Blotter features an integrated power supply optimized to provide consistent, high-efficiency protein delivery when used with commonly used precast or homemade gels (SDS-PAGE) and nitrocellulose or PVDF membranes.

Dry Electrotransfer (Dry Transfer)

Dry electroblotting methods use a special transfer sandwich containing innovative ingredients that eliminates the use of traditional transfer buffers. Instead of buffer tanks or wetted filter papers, a unique gel matrix (transfer stack) containing buffer is used. The high ion density in the gel matrix ensures rapid protein transfer. During staining, the copper anode does not produce oxygen gas as a result of water electrolysis, which reduces stain degradation. Conventional protein transfer techniques, including wet and semi-dry, use inert electrodes that produce oxygen. Typically, the shortened distance between the electrodes, the higher field strength, and the higher current reduce the transfer time.

Dry electroblotting transfer. The Invitrogen iBlot 2 Dry Blotting System provides fast western transfer without the need for buffers. This system efficiently blots proteins from acrylamide gels in 7 minutes or less, and is compatible with both PVDF and nitrocellulose membranes. The iBlot 2 System has performance comparable to traditional wet transfer methods in a fraction of the time.

Semi-dry electroblotting transfer. The Invitrogen Power Blotter is specifically designed for rapid semi-dry transfer of 10-300 kDa proteins from polyacrylamide gels to nitrocellulose or PVDF membranes in 5-10 minutes. The Power Blotter features an integrated power supply optimized to provide consistent, high-efficiency protein delivery when used with commonly used precast or homemade gels (SDS-PAGE) and nitrocellulose or PVDF membranes.