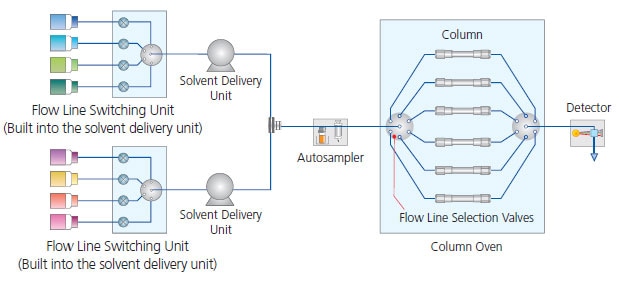

To separate multiple components, analysis and fractionation parameters need to be optimized, which requires a lot of work. Shimadzu provides the Method Scouting system that investigates conditions on an analytical level. The Method Scouting system enables efficient method development by fully automating method discovery, where combinations of mobile phases and columns are automatically changed, balanced and evaluated.

In addition, the Preparative Purification HPLC System enables optimization of the fractionation parameters by performing automated simulations using the preliminary results. This reduces the work associated with mobile phase solvent and research conditions that save samples.

Using the Nexera™ Prep Preparative HPLC System saves on labor when scaling up from the development of analytical conditions to the conditions for preparative work.

LabSolutions™ software provides simulation functions that reduce the labor involved in investigating conditions for analytical and preparative work.

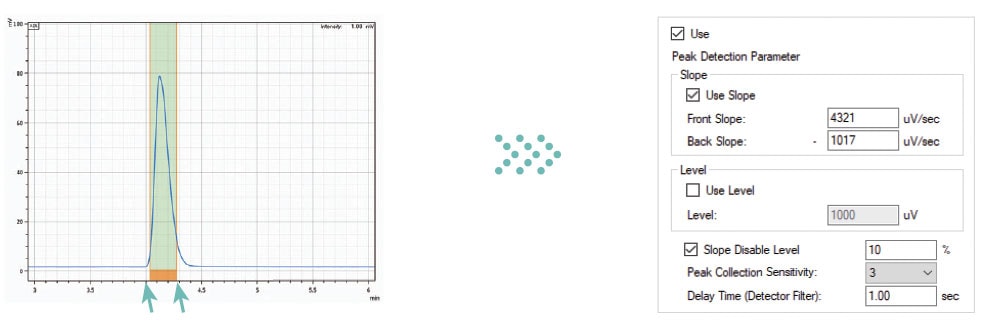

With the LabSolutions fractionation simulator (patent pending), specify the peak segment in the chromatogram to fractionate, and the system automatically sets the parameters required for fractionation. This reduces the time spent on setting fractionation conditions to about 1/4 the typical expenditure.

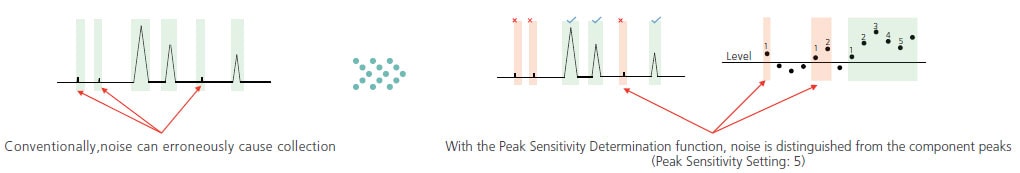

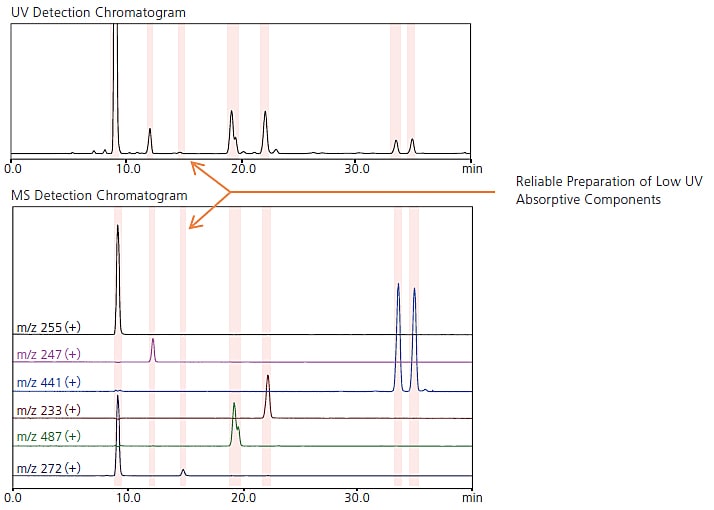

When configuring fractionation via automatic peak recognition, noise in the chromatogram is sometimes mistaken for component peaks, resulting in an insufficient number of test tubes for intended collection or improper positioning of collected fractions. With the LabSolutions software Peak Sensitivity Determination function (patent pending), peaks are recognized from the number of data points consecutively exceeding the configured threshold value, to determine whether to fractionate.

With LH-40 and FRC-40 able to perform signal-based logic and collection on up to four signal channels, not having a chromophore is not a limitation. Nexera Prep can use LCMS, RID, and ELSD to detect and/or identify targets for purification.

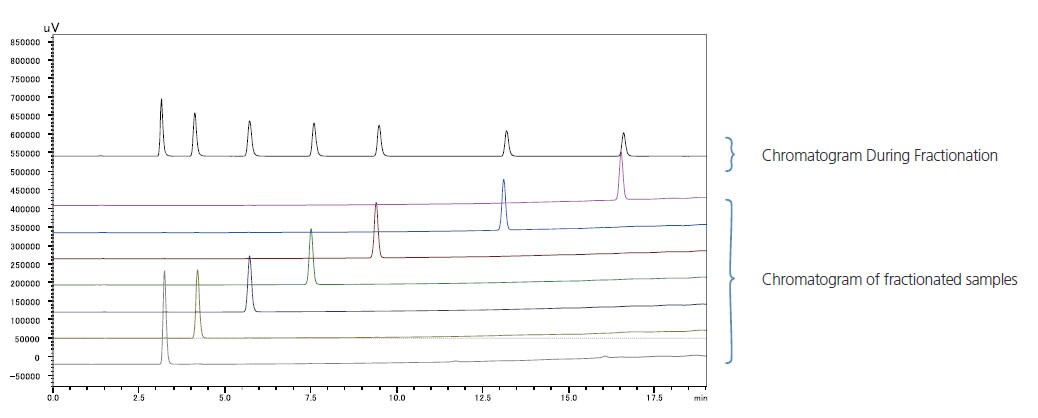

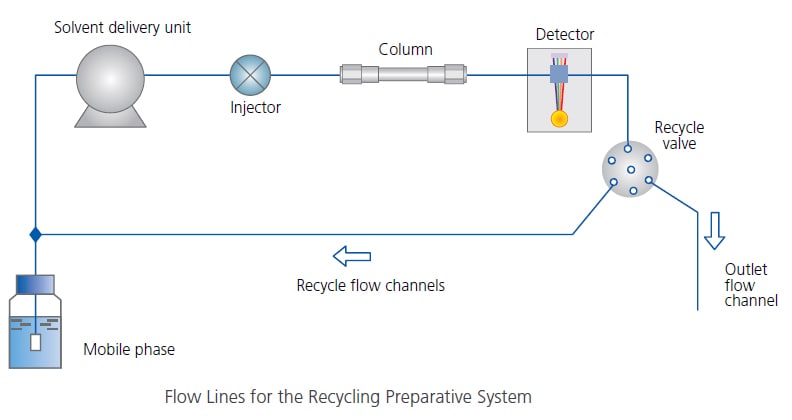

By repeatedly cycling the sample through the column, the target component can be resolved and recovered from coeluting species or impurities without the need for longer or multiple columns.

Long preparative columns are expensive, as such there is a need to use comparatively lower cost short columns effectively.

In the recycling separation method (closed valve recycling), the eluate liquid containing the target components that has eluted from the separation column is recycled into the column, enabling an equivalent separation capacity to that of a longer column.

The solvent delivery unit and fraction collector can be selected to suit the recovery volume.

Additionally, the Shim-pack™ Scepter features excellent scalability from analysis to preparative work, and the preparation of a variety of components is supported by an ample lineup.